Road foundation studies

A mobile team of specialists performs measurements of the deformation modulus of roadbeds and various substrates using dynamic and static plates, determines the compaction coefficient and soil density. Performs sample selection at facilities, performs measurements of unevenness of substrates and asphalt concrete surfaces.

Head of Service Dalius Sakalauskas

Please send inquiries and orders by e-mail to lbc@lbc.lt

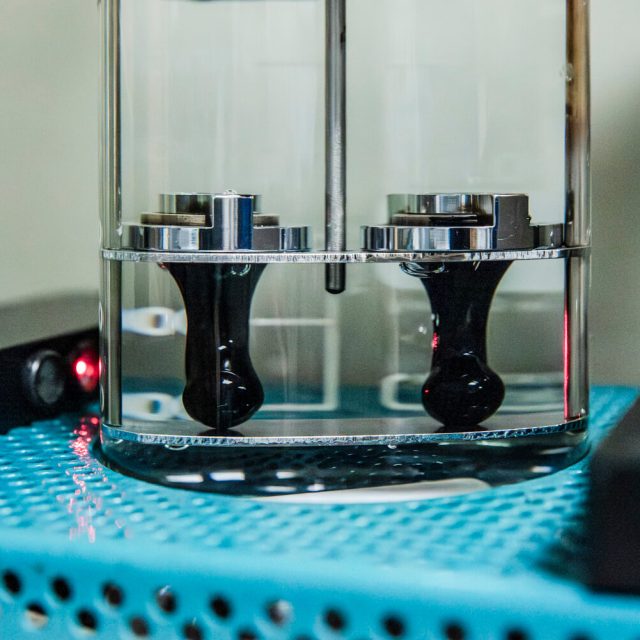

Concrete tests

The Concrete Testing Service performs tests on concrete mixtures, concrete products (environmental management elements, curbs, paving blocks, slabs, etc.), natural stone, and construction mortars. Concrete tests are also performed using non-destructive methods. Qualified specialists perform mechanical and chemical cement tests: compressive strength, setting time, expansion, V/C ratio, alkalis, caustics, insolubles, sulfates, water-soluble hexavalent chromium, etc. The service performs product suitability, self-control, and certification tests.

Please send orders to lbc@lbc.lt

Head of the Concrete Testing Service Loreta Valentinavičienė

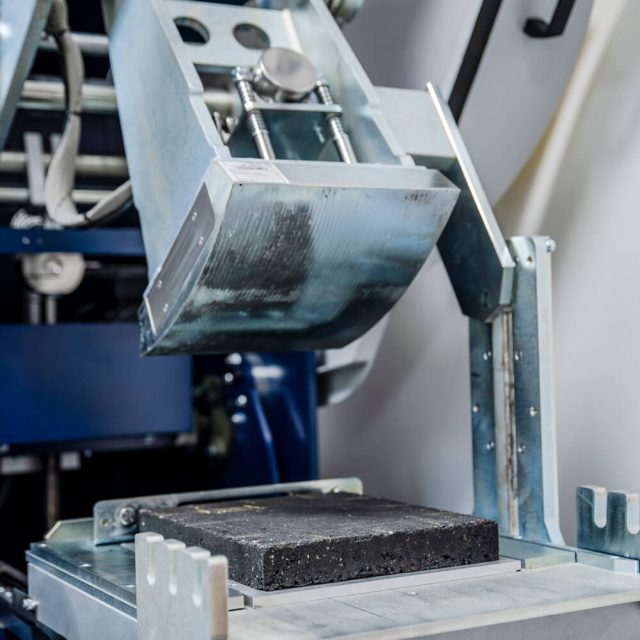

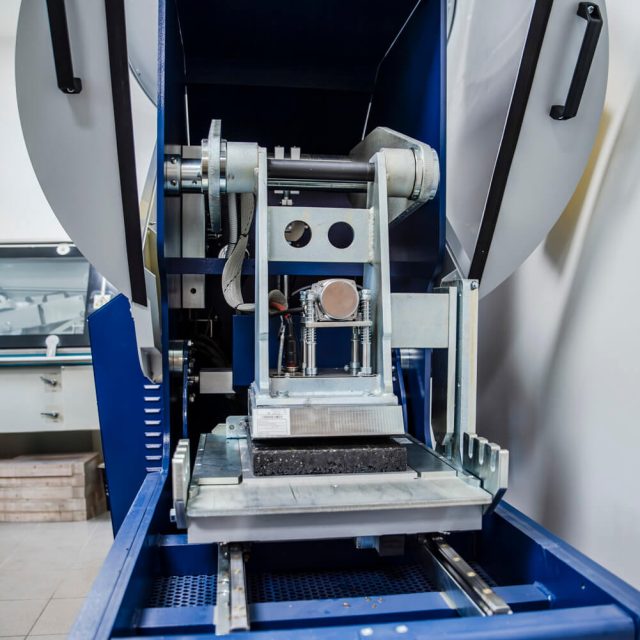

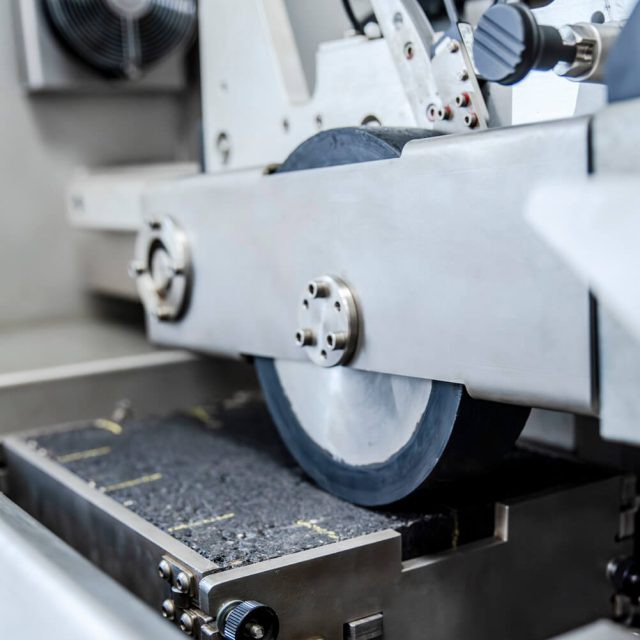

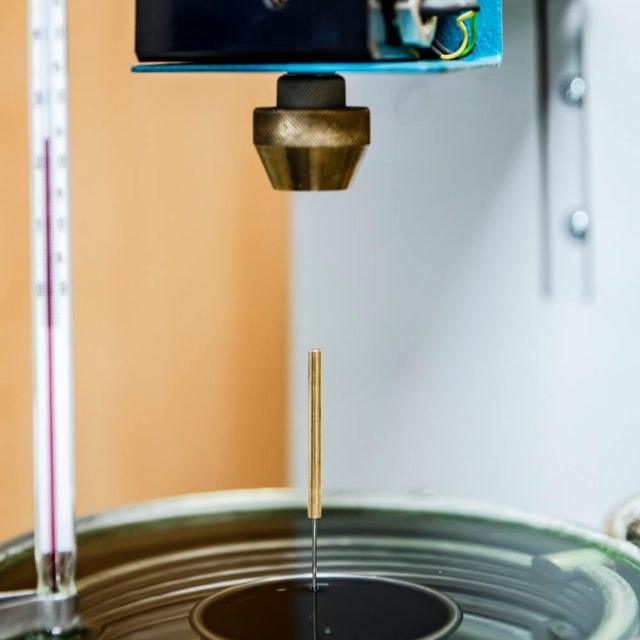

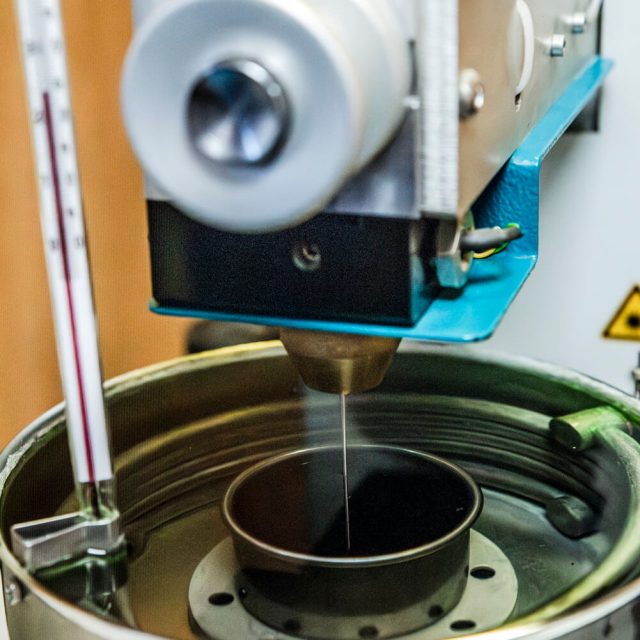

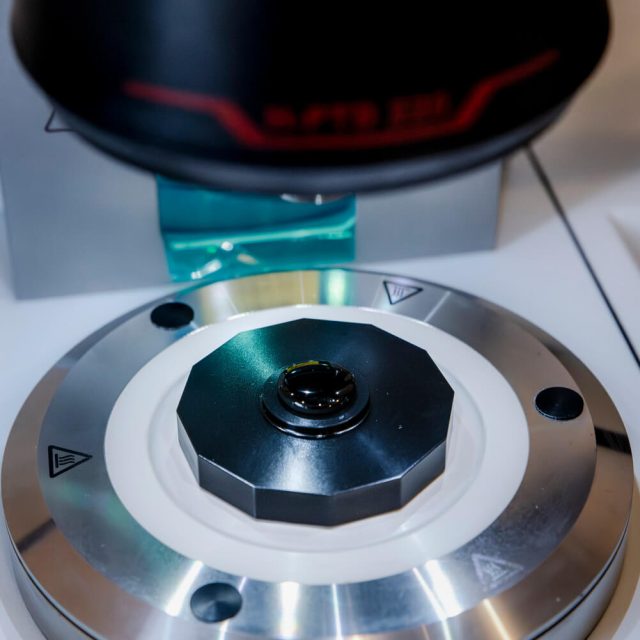

Asphalt concrete and aggregate tests

The tests are performed on aggregates, mineral powders, bitumen, bituminous binders, asphalt concrete mixtures, suitability, self-control and control tests of pavements. The degradation of pavements, the introduction of new materials are investigated in order to determine the causes of deformations of asphalt concrete pavements.

New asphalt concrete mixture compositions are designed.

The main tests are qualitative tests of asphalt concrete mixtures – determination of stability and plasticity according to Marshall, void content, granulometric composition of mixtures, binder content, Proctor density, compaction coefficient.

Please send orders by e-mail to lbc@lbc.lt

Head of Asphalt Concrete Testing Service Irena Skarelienė

Road construction works technical supervision service

The company’s technical maintenance service consists of highly qualified specialists with many years of experience who can perform technical maintenance of: special structures, special construction works, residential and non-residential buildings; engineering networks: water supply and sewage disposal; hydraulic structures; other engineering structures.

Specialists also perform technical maintenance of special construction works in the project parts – electrical engineering (up to 110 kV voltage), relay protection of voltage main electrical equipment, automation, up to 400 kV voltage substations and switchgear electrical equipment, electronic communications (telecommunications), security alarms, fire alarms, process control and automation systems, immovable cultural heritage protection objects.

Employees of the technical maintenance service analyze design solutions, submit proposals within their competence, participate in planning material and product tests, carry out material and product selections for tests, participate in self-control tests carried out by Contractors, evaluate test results and make decisions.

Head of Service Darius Pasvenskas

Test equipment sales and service

UAB Laboratorinių bandymų centras, based on its practical experience, supplies laboratory equipment that complies with European standards and provides full maintenance and servicing support in Lithuania.

Upon client request, the company also organizes training on the correct use and operation of the equipment.

For more detailed information about the offered laboratory equipment and consultations, please contact our company directly.

For equipment inquiries, please contact: